Setup dedicated to the deposition of thin and ultra-thin films deposited by electron beam evaporation.

Electron beam evaporation is a type of physical deposition by vapor phase in which electrons impinge at high velocity on the material to be deposited (target), typically in the form of bars or pellets, inducing thus sublimation and subsequent deposition on a substrate.

Inside the vacuum chamber, the target material is placed in a crucible where it's struck by the electron beam through the action of an electromagnetic field. The system uses a multi-crucible system which allows the deposition of multiple layers in the same session.

To improve the homogeneity of the deposition, the substrates are mounted on a rotating support, the speed of which can be controlled by the operator.

The system is equipped with an electro-pneumatic shutter and a quartz microbalance for an accurate control of thickness with sub-nanometer resolution. This technique is very versatile and allows the deposition of thin films (metal or oxides) with thickness ranging from few atomic layers to few micrometers of material.

TECHNICAL SPECIFICATIONS

-

Base pressure < 10-8mbar

-

1.5 kW electron gun driven by Temescal TemEBeam EBC controller;

-

Possibility to load up to four different deposition materials;

-

Thickness of samples measured by quartz microbalance.

AVAILABLE TECHINQUES

- e-beam evaporation

SAMPLES

- Any wafer up to 6 inches in diameter

USED FOR

- Deposition of thin and ultra-thin films;

- Growth of coatings with low electron affinity on semiconductors.

Case studies

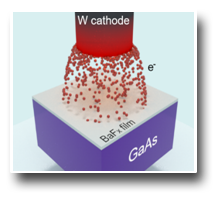

Ultra-thin films of barium fluoride with low work function for thermionic-thermophotovoltaic applications

Through deposition by evaporation with electron beam it was possible to verify the effectiveness of the thin and ultra-thin coatings of barium fluoride in reducing the working function of GaAs wafers from 4.6 eV to 2.1 eV.

The study was made by analyzing the thickness and composition of the coatings. Their potential application is in thermionic-photovoltaic hybrid systems.

See: V. Serpente et al., Mater. Chem. Phys 249 (2020) 122989

English (UK)

English (UK)  Italiano (Italia)

Italiano (Italia)