ns-PLD (@ 248 nm) in HV or controlled atmosphere

Gaspare Varvaro -

Laboratory of Nanostructured Magnetic Materials: nM2-Lab

TECHNICAL SPECIFICATIONS

-

Excimer laser KrF (248 nm) LPX 105-Lambda Physik; applied voltage: 19 - 26 KV; frequency: 2 - 15 Hz; pulse duration: 17 ns

-

2 high-vacuum deposition chambers (DC-1, DC-2)

-

Pumping system (primary pump and turbomolecular pump, P > 10-8mbar) and load-lock for sample charging (DC-2)

-

Variable substrate – target distance

-

Multi-Target holder systems for depositing different materials (DC-1: max 4, DC-2: max 8)

-

Substrate temperature: 25 - 800°C

-

Rotating and tilting sample-holder (DC-2)

-

Needle valve for depositions under controlled atmosphere: Ar, N2, O2, He

AVAILABLE TECHNIQUES

- Deposition of metals and alloys in high vacuum and/or controlled atmosphere and at variable temperature.

- Growth of oxide films from metallic targets under an O2 reactive atmosphere or from ceramic targets.

- Post-annealing heat treatments in high vacuum or controlled atmosphere, up to a maximum temperature of 800 °C, with variable and controlled duration.

SAMPLES

-

Thin films with a variable thickness between 2nm - 2µm. substrate dimension: 1.5 x1.5 cm2 (DC-1), 3.5 x3.5 cm2 o Φ = 5 cm (DC-2). larger homogeneity area: 5x5 mm2(DC-1), 3.5 x3.5 cm2 o Φ= 2 cm (DC-2)

-

The targets can be purchased from the main supply companies. Alternatively, it is possible to produce and/or use sintered targets from laboratory synthesized powders.

USED FOR

- Growth of magnetic and non-magnetic thin films and multilayer heterostructures (metals, oxides, alloys) for fundamental studies and applications (biomedicine, sensors, information storage).

- Heat treatments (annealing) for morphological and/or structural transitions.

CASE STUDIES

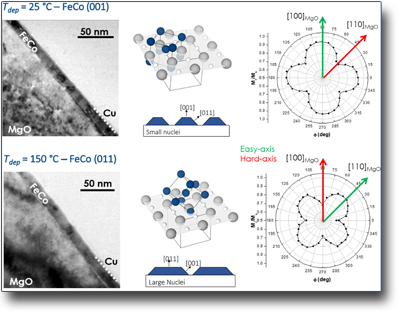

Highly textured FeCo thin films

The peculiarity of this growth technique, thanks to the high energy of the species coming from the ablation process, allowed to obtain CoFe magnetic alloy films with high crystallographic quality even at low deposition temperature (T <150 ° C). The structural properties, investigated by XRD and HRTEM measurements, allowed the correlation of the crystallographic orientation with the substrate temperature, discussed in the framework of a growth model that takes into account the thermodynamic and kinetic aspects characteristic of the deposition process. The magnetic characterization of the films, carried out using an angular VSM magnetometer, demonstrated a perfect correlation between the crystallographic directions, in the two samples, and the axes of magnetocrystalline anisotropy.

See: G. Varvaro, et al. ACS Applied Materials and Interfaces 7, 22341 (2015)

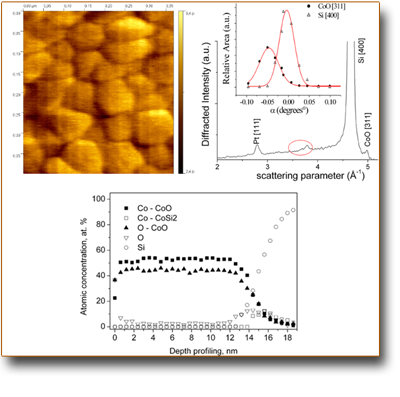

Growth of CoO films from metallic target under a controlled atmosphere

Through a deposition at 400°C under a controlled O2 atmosphere it was possible to grow cobalt oxide (CoO) thin films with a high quality in terms of chemical composition, structural order and surface roughness. These features make these films suitable for fundamental studies of interface magnetic exchange coupling, where the structural and microstructural properties strongly affect the magnetic properties of the systems. By varying the growth parameters, in particular the temperature of the substrate and the O2, it is possible to drastically vary the stoichiometry and the structural properties of the samples, demonstrating the great versatility of the technique.

See: S. Laureti et al., Applied Surface Science 254, 5111 (2008)

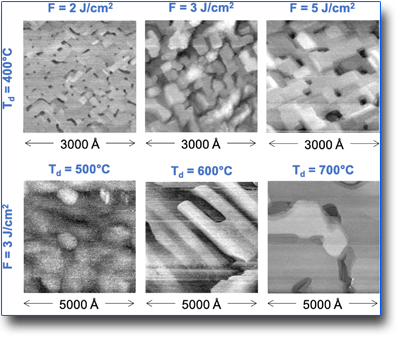

Growth of Pt films on MgO (100) as a function of the deposition parameters

The study of Pt thin films as a function of growth parameters (substrate temperature, fluence and duration of the process) was carried out with the aim of finding the best experimental conditions for having controlled crystallographic orientation, size grain, roughness. Indeed, the use of metal underlayers in ICT applications requires a high control over the morphological and structural quality of the films; the versatility of the technique and the possibility of varying a large number of parameters made it possible to identify the different growth mechanisms of Pt on MgO (100) and to correlate the process parameters with the morpho-structural properties of the samples.

See: G. Scavia et. al, The Journal of Physical Chemistry B110, 5529 (2006)

English (UK)

English (UK)  Italiano (Italia)

Italiano (Italia)