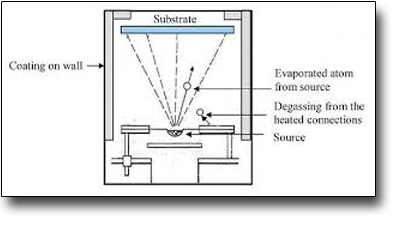

Setup dedicated to the deposition of thin and ultra-thin films deposited by thermal evaporation. Thermal evaporation is one of the oldest thin film deposition techniques. Currently it's more important in research laboratories rather than in the industrial field. In its simplest form, a current with considerable intensity passes through a metal crucible with high melting temperature (for example Tungsten, Molybdenum), shaped to accommodate the material to be evaporated. Alternatively, the crucible can be made of ceramic material heated radiatively or by the means of a metal wire immersed in the crucible.

The basic stages of the process are the following:

- sublimation of a solid or evaporation of a liquid in order to form an aeriform species;

- transport of atoms or molecules from the source to the substrate to be coated;

- deposition of particles on the substrate and growth of the film.

The vaporized material reaches the substrate with no or only few collisions with the residual gas molecules present between the source and the sample. Usually the coating phase takes place at a pressure between 10-2Pa and 10-5 Pa depending on the level of contamination that can be tolerated. In absence of collisions, the particles travel in a straight path between source and substrate (line-of-sight. In general, the total area of vaporization during thermal evaporation is small, the incident flux has a strong dependence well represented by the cosine of the angle between the normal to the crucible and the direction of the joint of the crucible with the substrate, so that for an angle at 00 there is the maximum flow. The chamber necessary for the deposition is characterized by a relatively large distance between the source and the substrate; this minimizes the radial heating from the source itself, allowing also the movement of the structure that supports the substrate during deposition.This technique is very versatile and allows the deposition of thin films (metallic or oxides) with thickness ranging from a few atomic layers to a few micrometers of material.

TECHNICAL SPECIFICATIONS

-

High Vacuum pressure < mbar< 10-5 mbar

-

Possibility to load up to four different deposition materials

-

Thickness of the samples measured by a quartz microbalance

SAMPLES

- Any wafer up to 15cm in diameter

USED FOR

- Deposition of thin and ultra-thin films in the field of optics and electron microscopy

English (UK)

English (UK)  Italiano (Italia)

Italiano (Italia)