Measurements of dielectric permittivity are made also on thin films with parallel electrode configuration or in-plane surface capacitors. A ferroelectric tester (Radiant Technologies) provided with a high-voltage interface and a high-voltage amplifier is used for the polarization-electric field characterization of ferroelectric materials.

TECHNICAL SPECIFICATIONS

- Dielectric Spectroscopy

- Linkam cell + HP LCR/HP impedance bridge: Temperature range 90 – 870 K, Frequency range 20 Hz- 40 MHz. Inert atmosphere.

- HP LCR/HP Impedance Bridge + Delta Design chamber (90 – 570 K, 20 Hz- 40 MHz). Air atmosphere.

- AC diving signal can be varied between 0.01 V – 1 V. Measurements can be done also under an applied DC field up to 40 V.

- Ferroelectric tester

- Radiant Technologies probe+ HV interface + HV Trek amplifier up to 4 kV.

AVAILABLE TECHNIQUES

- Dielectric spectroscopy

- Measurements of dielectric permittivity function of temperature and frequency (90 – 870 K, 20 Hz- 40 MHz).

- Variation of dielectric permittivity with the DC applied electric field (0-40 V).

- Frequency dispersion of dielectric permittivity in inhomogeneous media or materials with defects; relaxation phenomena and activation energies.

- Phase transitions in polar/antipolar materials.

- Ferroelectric tester

- Measurements of polarization hysteresis in ferroelectric/antiferroelectric materials.

- Dependence of dielectric permittivity on voltage

- Measurements of leakage currents.

SAMPLE

-

Sample lateral dimensions: up to 12 mm for Linkam chamber or larger (20-40 mm) for Delta chamber.

-

Sample thickness: about 0.5 mm for Linkam chamber or larger (2-3 mm) for Delta chamber.

-

The samples should not be conductive.

-

Thin film samples can be measured in parallel electrode configuration or as in-plane surface capacitors.

USE FOR

-

Ferroelectric/antiferroelectric materials

-

Relaxor materials

-

Organic-inorganic halide perovskites

-

Piezoelectric/polymer composites

-

Heterogeneous dielectric materials

-

Thin film dielectric characterization

CASE STUDIES

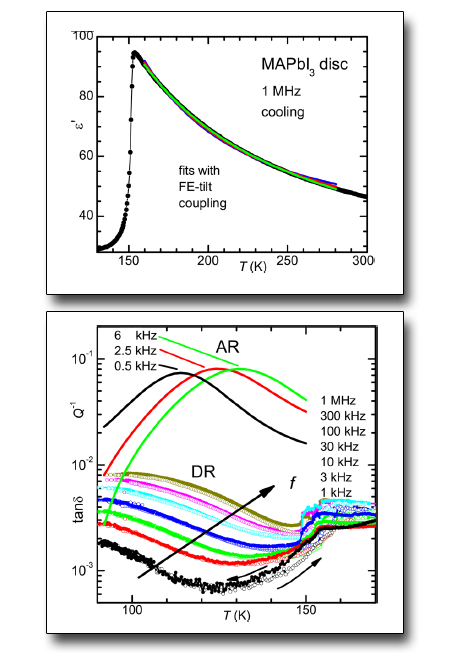

The real part of the permittivity measured during cooling on CH3NH3PbI3 (MAPbI3) a 1 MHz

The disc samples have been obtained by pressing powder of MAPbI3 and by applying silver electrodes on two parallel surfaces. It can be observed that there is no transition at room temperature, therefore a normal ferroelectric state as invoked in the literature cannot be supported. The rise of dielectric permittivity below room temperature is typical of paraelectric reorientation of the MA dipoles and is strongly influenced by the coupling with the tilted surrounding PbI6octahedra.

Dielectric and anelastic losses on the same sample.

Although a dielectric relaxation exists at low temperatures, it is much slower than the anelastic one and with small intensity. Being a very broad anomaly, it might be related to the relaxation of the walls between the different variants of orthorhombic domains.

See: F. Cordero, F. Craciun, F. Trequattrini et al., J. Phys. Chem. Lett. 9, 4401 (2018)

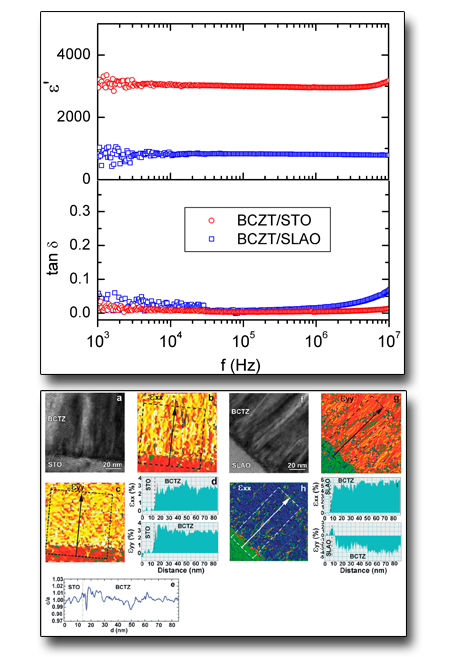

(Ba,Ca)(Zr,Ti)O3 thin films grown on different substrates show very different dielectric properties

Lead-free BCZT thin films show high dielectric permittivity and piezoelectric properties, which make them very appealing for energy harvesting applications. Dielectric spectroscopy measurements evidenced a huge increase of dielectric permittivity with respect to bulk for thin films grown epitaxially on SrTiO3 substrates. This has been correlated with results from HRTEM and geometrical phase (GPA) analysis which show that the origin of the increased dielectric permittivity resides in the appearance of nanoscale domains as a result of epitaxial strain relaxation.

See: N. Scarisoreanu, F. Craciun, A. Moldovan et al

ACS Appl. Mater. Interfaces 7, 23984 (2015)

English (UK)

English (UK)  Italiano (Italia)

Italiano (Italia)