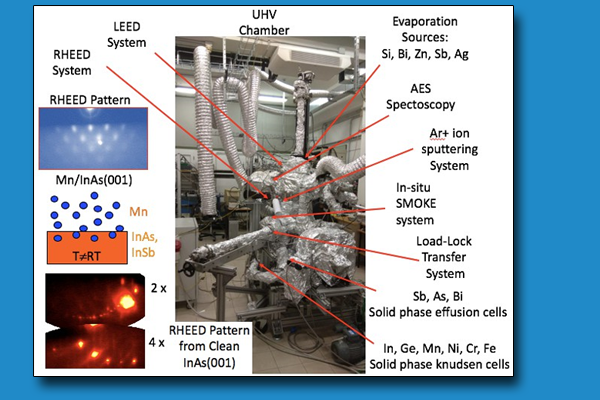

III-V MBE 2 growth system MBE2 (III-V)

Paola De Padova -

Carlo Ottaviani -

Sandro Priori -

Laboratory IC11

In epitaxy the surface is exposed to a gas, for example, Metal (M)/Semiconductor (SC) vapor, which condenses on the surface. In this way the surface becomes a contact place between two solids which is called: interface. The fundamental question in epitaxy is whether the gas atoms adsorbed on the surface wet the surface or form islands. This case occurs as a result of strong forces between adsorbate and surface atoms (at T=0): this is a typical case of adhesion. If the adsorbate-adsorbate interaction is stronger than adsorbate-surface interactions, islands form on the surface, which are termed clusters. Hence, the wetting properties of a “gas” upon a specify surface are the necessary conditions for the epitaxial growth.

TECHNICAL SPECIFICATIONS

- Working pressure ~10-10 mbar mbar

- In, Ge, Mn, Ni, Cr, Fe effusion cells;

- Sb, As, Bi- Surfactants effusion cells;

- Ag, Zn- Capping Layer effusion cells;

- DC direct sample heating (RT-1200 °C) and Indirect heating (RT-450 °C ) systems

- Air-vacuum Fast Load-lock Sample Transfer System;

- Quartz Microbalance;

- Ar+ Ion sputtering system;+;

- O Gas-line;

- e-- HV variable (0-15) KeV for for RHEED system;

- e-- HV variabile (0-0.5) KeV for LEED system;

- AES/SE/REELS spectroscopies; double-pass CMA, e- (HV = 0-5) KeV;ΔE=1.2%PE (UPS/ESCA); ΔE=1.2%Ekin eV (AES);

- In-situ lock-in

- SMOKE system.

- H-Speed Camera real-time for data diffraction PATTERN acquisition (Image-software-MAC).

AVAILABLE TECHNIQUES

- Ultra-High Vacuum (UHV) System for Surface Science Investigations:

- LEED/RHEED/AES/SE

REELS/SMOKE systems; - Chemical composition chemical bonding at surface; work function, molecules hybridization and valence orbitals investigation;

- Diffraction pattern

from low- and -high e-; - Surface magneto-optics Kerr effect;

- Analysis of samples in the presence of a gases (O and other);

- Heating/cooling (LN) of samples from ~ 80 to 1200 °C during analysis;

- Clean Semiconductor (SC), Metal (M)-Surfaces reconstruction

- Epitaxial growth SC/SC, SC/Metal/SC;

- Homo- and Hetero-structures growth: 1D, 2D and 3D Materials.

SAMPLES

-

Sample lateral dimensions: 10 x 5 mm (ideal), 3 x 3 mm (minimal), 10 x 10 mm (maximal);

-

Sample thickness: ideally up to 2 mm (thicker and/or smaller samples also feasible).

USED FOR

-

Fundamental Surface Science study;

-

Artificial Atomic Epitaxial Growth;

-

Discovery of new 1D, 2D and 3D epitaxial SC/SC; M/SC for micro-nanoelectronics and solar cells purposes;

-

Semiconductor/ Microelectronics;

-

Microcircuits;;

-

Ultra-thin Films;

-

Samples Cleaning;

-

Thin-film Stability;

-

Barrier Layers;

-

Lubrication;

-

Chemical Industry;

-

Coatings/Catalysis.

English (UK)

English (UK)  Italiano (Italia)

Italiano (Italia)