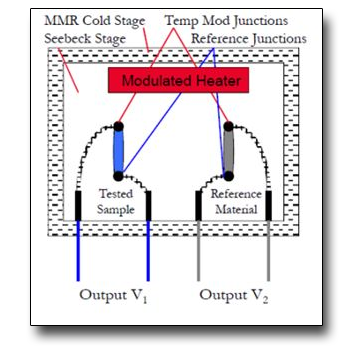

It allows the analysis of thermoelectric materials over a temperature range from -70 to 450 °C. The apparatus is composed of a cryogenic vacuum chamber, inside which the sample to be analysed is mounted, and an electronic unit that manages both the detection of the thermal tension generated, by means of precision nano-voltmeters, and the temperature control. The system connects through the use of the RS-232 communication standard to a workstation, on which the management software is installed.

The measurement process adopted by this system involves the comparison between two thermo-generated voltages, one developed from a known material (copper or constantan) and taken as a reference, and the other generated by the material under test. Knowing the coefficient of the reference material it is possible to extrapolate, through simple analytical calculations, the coefficient of the sample under analysis.

TECHNICAL SPECIFICATIONS

-

Temperature Range: -70 °C to 450 °C;

-

Base pressure: 5 x 10-3 mbar;

-

Highly accurate Seebeck coefficient measurement with a resolution of 50 nV;

-

Generates a temperature difference across sample, power available Min: 0.01W, Max: 1W;

-

Sample Length: >2 mm and <10 mm.

SAMPLES

-

The samples must have threadlike geometry with a diameter of 1 mm and a length equal to about 5 mm to try to reproduce the shape of the reference sample as closely as possible;

-

For thin films, they must be grown on thin alumina cylinders with a diameter of 1 mm and a length equal to about 5 mm to try to reproduce the shape of the reference sample as closely as possible.

Case Studies

ZnSb-based thin films prepared by ns-PLD for thermoelectric applications

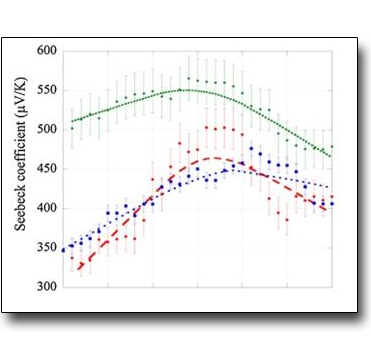

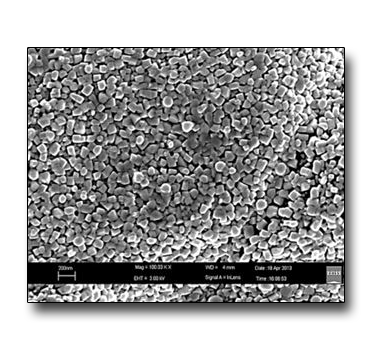

Zinc antimonide-based nanostructured thin films were produced by Pulsed Laser Deposition (PLD) using a ns-ArF laser (193 nm) and a multi-target deposition system. The films were prepared according to a multi-layer structure, obtained by adding different dopants (Cr, Ag) within the ZnSb matrix.

A. Bellucci et al., Appl. Surf. Sci. 418 (2017) 589-593

Nano-crystalline Ag–PbTe thermoelectric thin films by a multi-target PLD system.

It has been evaluated the ability of ArF pulsed laser ablation to grow nano-crystalline thin films of high temperature PbTe thermoelectric material, and to obtain a uniform and controlled Ag blending, through the entire thickness of the film, using a multi-target system in vacuum.

E. Cappelli et al., Appl. Surf. Sci. 336 (2015) 283-289

English (UK)

English (UK)  Italiano (Italia)

Italiano (Italia)