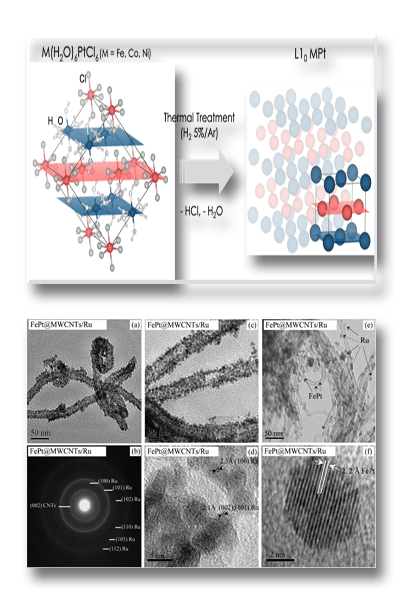

Permanent magnets have become increasingly important in different technological fields such as electric motors both for locomotion and for other uses. Driven by climate change, governments are encouraging the production of electric or hydrogen cars. In both case permanent magnets made of magnetic metal alloys with high energy product (BHmax) are required to build light motors and replace rare earth (RE) permanent magnets such as NdFeB or SmCo. In our laboratory a method has been developed for the synthesis of chemically ordered alloys L10 (fig below) which show a high magnetic anisotropy and a high BHmax. We have already tested the principles of this method for the synthesis of other binary alloys such as FePt, CoPt, NiPt, etc. The focus of the research is now the study of low cost alloys (FeNi, FeCo, etc.) to obtain lighter and higher performance permanent magnets, without RE.

Nanocomposites have the ability to combine different materials to exploit their different properties synergistically. Our laboratory has a consolidated experience in the synthesis of nanocomposites (NCs) based on magnetic nanoparticles linked to Carbon Nanotubes (CNTs) or Graphene. These materials are useful in various fields such as chemical catalysis, water purification, etc. The new nano-architectures developed have three main components such as Ru / CNTs @ FePt. In these nanocomposites the Ru is the catalyst, the CNTs are used as a dispersing surface and the FePt NPs inside the CNTs provide the magnetic properties (fig. right panel).

Staff: Elisabetta Agostinelli, Aldo Capobianchi, Sara Laureti, Alberto Maria Testa, Gaspare Varvaro (nM2-Lab group)

English (UK)

English (UK)  Italiano (Italia)

Italiano (Italia)