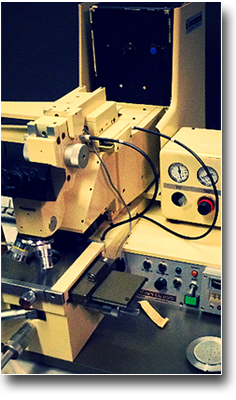

The photolithography setup is composed by a Karl Süss MA6 mask aligner, able to reach a resolution down to 1 μm, and a SUSS MicroTec LabSpin spin coater, maximum speed 5000 rpm. The setup is mounted in a clean room to improve the cleanliness of lithography process. The MA6 mask aligner is ideal for use with I-line (365 nm) resists. It is possible to use both positive and negative photoresist, with thickness up to 30 μm.

TECHNICAL SPECIFICATION

-

350 W UV lamp (350-450 nm)

-

Positive and negative photoresist, thickness up to 30 μm

-

Lithographic mask size: 4-inch

-

Lithography modes: soft contact (resolution 1-2 μm), hard contact (resolution 1 μm)

-

Mask alignment with 3 different microscope objectives (5x, 10x, 20x)

AVAILABLE TECHNIQUES

- Photolithography

- Spin coating

SAMPLES

-

Maximum dimension allowed: 3-inch diameter

USE FOR

-

Preparation of contacts, pad, interdigitate structures

CASE STUDIES

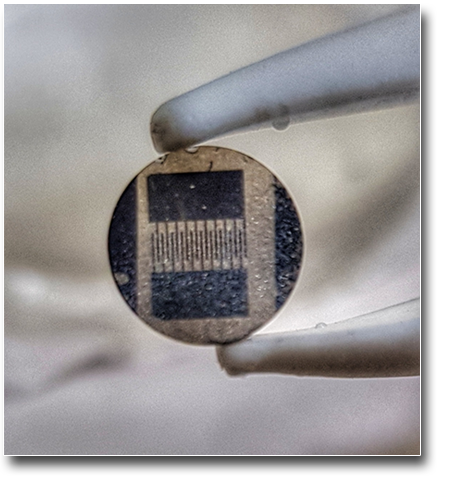

Lithographic pattern for contacts

In this case, the lithography has been used to fabricate a metallic contact, arranged as two pads and a central interdigitated region.

Phys. Rev. B, 10.1103/PhysRevB.97.115448

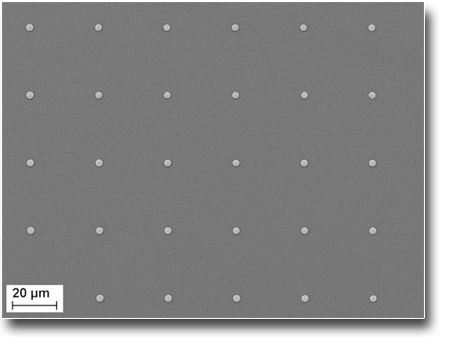

Other geometrical patterns

Photolithography can also be used for specific patterns as in this case, where Au columns have been grown on a GaAs substrate.

Photolithography can also be used for specific patterns as in this case, where Au columns have been grown on a GaAs substrate.

English (UK)

English (UK)  Italiano (Italia)

Italiano (Italia)