As the solvent evaporates the size of the droplet deceases and at the end a gas of molecular ions is formed. This approach provides ”dry deposits” at ambient pressure or in controlled atmosphere and can be easily automatized and applied on a large scale.

TECHNICAL SPECIFICATIONS

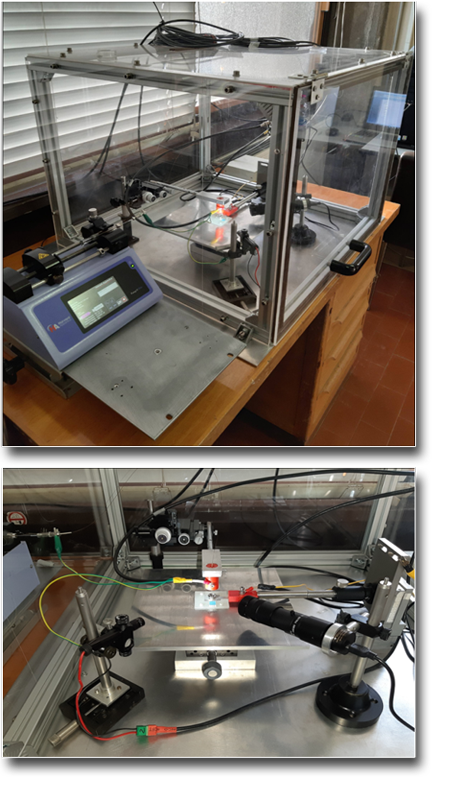

- Harvard Apparatus Pump 11 elite

- Hamilton 250 μl Gastight 1725 syringe

- Silica capillary 50 cm long and 250 μm inner diameter (Agilent Technologies)

- Metallic needle with size/shape variable according to needs (currently: flat-tipped steel needle, 2 cm long and 100 μm inner diameter, Vita Needles company)

- BRESSER MikrOkular Full HD digital camera equipped with a 6x16 mm2 10° monocular (SPECWELL)

- Two High voltage NIM power supplies (6 kV) for cone and needle (ORTEC, Mod 7716)

- LED light source

- sample holder for the SPE.

- Steel focusing cones with size/shape variable according to needs.

- Portable potentiostat PalmSens®4 (Palm Instrument, The Netherlands) for electrochemical measurements of biosensors.

- The surface on which to deposit via ESD need to be made of conductive material.

AVAILABLE TECHNIQUES

- Deposition of bioactive species on surfaces for the production of biosensors

- Surface materials already tested are gold, silver, aluminum, metal, stainless steel, graphite, carbon, carbon black, ito and conductive glass.

- The surface to be functionalized should preferably be flat and a few millimeters thick.

- Maximum deposition spot currently available is of circular shape and 2 cm in diameter (changes can be made to meet needs).

- Minimum deposition spot currently available is of circular shape and 3,5 mm in diameter (changes can be made to meet needs).

- All intermediate deposit sizes between 6,0 mm and 3,5 mm in diameters are available for circular spot.

SAMPLE

- Enzyme/proteins/plasmid/DNA/ antibodies preferably resistant in environments containing organic solvents such as methanol or ethanol and/or protonating agents.

- Nanoparticles (to be tested)

USE FOR

- catalysis

- thin film production

- biosensors production

- formation of layers of semi-conductive ceramics such as metal oxide films

- modification of silicon surfaces with layers of peptides to enhance the adhesion of living cells

- preparation of DNA and protein samples for scanning tunnelling microscopy

- antifouling or biocompatible coatings for medical devices

- biomaterial scaffolds for tissue engineering

- prepare surfaces with nanoparticles

Case Studies

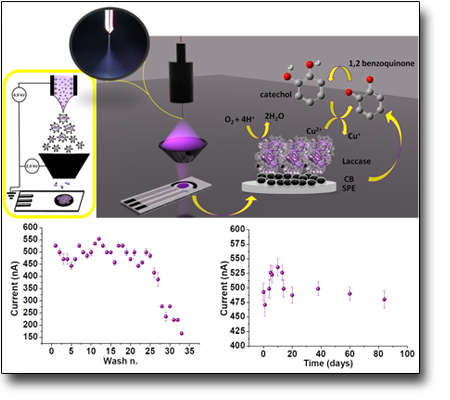

The ElectroSpray Deposition (ESD) has been exploited as a novel technique for the immobilisation of laccase enzyme on carbon black modified screen-printed electrodes. The aim was to fabricate an amperometric biosensor for phenolic compound detection in water. The electrodes produced by ESD have proved that this immobilisation technique is suited to manufacture high performance biosensors. The results show that the laccase enzyme maintains its activity after undergoing the electrospray ionisation process and deposition. The fabricated biosensor has excellent performances in terms of storage (up to 3 months at room temperature) and working (up to 25 measurements on the same electrode) stability.

See: ACS Sustainable Chem. Eng. 2022, 10, 5, 1888–1898 - Biosensors and Bioelectronics, 163, 2020, 11229

English (UK)

English (UK)  Italiano (Italia)

Italiano (Italia)