Hc = Hs0 + [Bs + 2c1t (Hf0-Hs0)] / D

where c1 = c (D / d) ≈ 0,5; Hf0 and Hs0 are intrinsic hardness of the film and substrate; Bs is a coefficient, which can be determined from a separate experiment on hardness of the substrate, and D is the imprint diagonal.

TECHNICAL SPECIFICATIONS

- Test Force 12 steps: 1 - 5 - 10 - 15 - 25 - 50 - 100 - 200 - 300 - 500 - 1000 - 2000 (p)/(gf)

- Automatic loading procedure.

- Dwell time 6 – 99 s 5- 99 s.

- Approach velocity 25 to 60 µm/s (selectable in steps of 5 µm/s)..

- Optics Filar:

- Standard objectives C PLAN 10x/0.22 – 7.8 mm free working distance;

N PLAN 50x/0.75 – 0.37 mm free working distance (spring loaded).

- Standard objectives C PLAN 10x/0.22 – 7.8 mm free working distance;

- Specimen Stage:

- Stage size 135 x 135 mm;

- X/Y travel 25 x 25 mm.

- Positioning increment 0.01 mm.

- Maximum specimen height on stage 90 mm.

SAMPLE

-

Sample lateral dimensions: 25 x 25 mm (maximal)

-

Sample thickness: 90 mm (maximal)

-

Deposited film samples

USE FOR

- Surface phenomena

- Surface treatment

- Case-hardening of steels

- Surface hardening of titanium

- Electrodeposited coating: hardness, brittleness, adhesion

- Effects of various mechanical and thermal treatments on the surface layers

- Study of Alloys and Alloy Constitution

- Quantification of transition areas

- Determination of the Effect of Thermal Treatment

- Heat treatment of steels, non-ferrous alloys,

- precipitation treatments and age-hardening

- Segregation and coring, rates of diffusion

- Recrystallisation

- Materials science

- Brittleness: ratio hardness/toughness

- Elastic/plastic properties

- Correlation with Young modulus

- Paint films – hardness of painted surfaces

- Tribology Research

- Work hardening

- Estimate mild wear losses

- Correlation hardness number – wear resistance

- Metal Powder Particles

- Mechanical properties

- Durability and performance of alloy components and ceramics

- Determination of the hardening degree of glaze

CASE STUDIES

Fe-doped hydroxyapatite coatings for orthopedic and dental implant applications

Transient absorption measurements on 3D Au nanoparticle (NP)-decorated

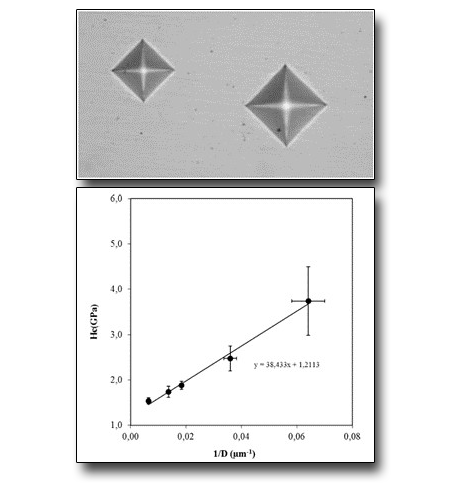

SiO2 nanowire arrays. The 3D NP array has been produced by the dewetting of a thin Au film deposited on silica nanowires produced by oxidation of silicon nanowires. We demonstrate that the width of the experimental spectra, the energy shift of their position with time, and the asymmetry between the two positive wings in the dynamical variation of absorption can all be attributed to the nonuniform shape distribution of the Au NPs in the sample.In the present study, the Pulsed Laser Deposition technique was applied to coat titanium for orthopaedic and dental implant applications. Iron-substituted hydroxyapatite (Fe-HAp) (0.28 wt.% of Fe) was used as coating material since titanium itself is unable to elicit biologically functional bone/material interface. To examine the mechanical properties of the deposited films, the Vickers microhardness indentation technique was applied. For the film samples, the measured hardness was that of the film/substrate composite system. To discriminate the composite hardness of the film/substrate system (Hc) into its components, film(Hf) and substrate (Hs), the Jönsson and Hogmark model based on the “law-of-mixtures” approach was used. The obtained Fe-HAp nanocrystalline films possess the intrinsic Vickers microhardness as high as 17 GPa.

Julietta V. Rau et al. Appl. Surf. Sci. 2014, v. 307, pp. 301-305.

DOI: 10.1016/j.apsusc.2014.04.030

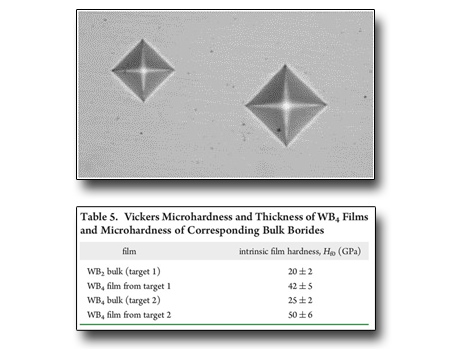

Attempts to synthesize and/or theoretically predict new superhard materials are the subject of an intense research activity. In this work, WB2 and WB4 polycrystalline bulk samples and corresponding films deposited on SiO2 by Pulsed Laser Deposition method were prepared and tested with Vickers microindentation technique at various loads to determine the Vickers hardness. The deposited films, 0.8 μm thick, were composed of WB4. The intrinsic hardness of films, calculated according to the Jönsson and Hogmark “law-of-mixtures” model, was in the superhardness region of 42-50 GPa.

Julietta V. Rau et al. ACS Appl Mater Interfaces. Appl. Mater. Interf. ACS, 2011, v. 3, pp. 3738–3743 DOI: 10.1021/am200927q

English (UK)

English (UK)  Italiano (Italia)

Italiano (Italia)