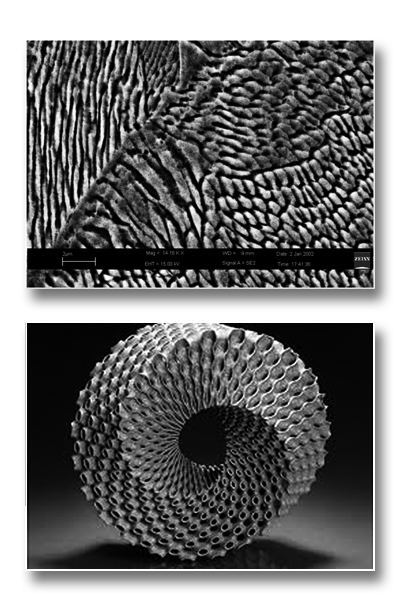

Additive Manufacturing (AM) or 3D printing of metallic components is one of the most promising advanced methods of manufac-turing for products of the future. The guideline documents of the European Commission always refer to this technology for its enormous perspectives in being developed for both its environmental sustainability and ability in realizing new kinds of products. This technology is based on the scanning of a laser beam which acting on a powder bed of material with defined composition and shape, can assemble, layer-by-layer, very complex components. ISM, thanks to its skills in deducing and modelling the laser-matter interaction processes, it is involved in research activities aiming to design new materials as well as determining the processes inducing the formation of defects. All activities and methodologies of research used in this field have highlighted that micro-structural and defect features are strongly connected to thermal gradients occurring during the AM’s process which can affect both, system and geometries to be developed and their specific application field.

Staff: P. Dolce, A.Guarnaccio, M.L.Pace, D. Mollica, G.P.Parisi, A. Santagata

English (UK)

English (UK)  Italiano (Italia)

Italiano (Italia)